ROBOTICS IN CONTROLLED ENVIRONMENTS

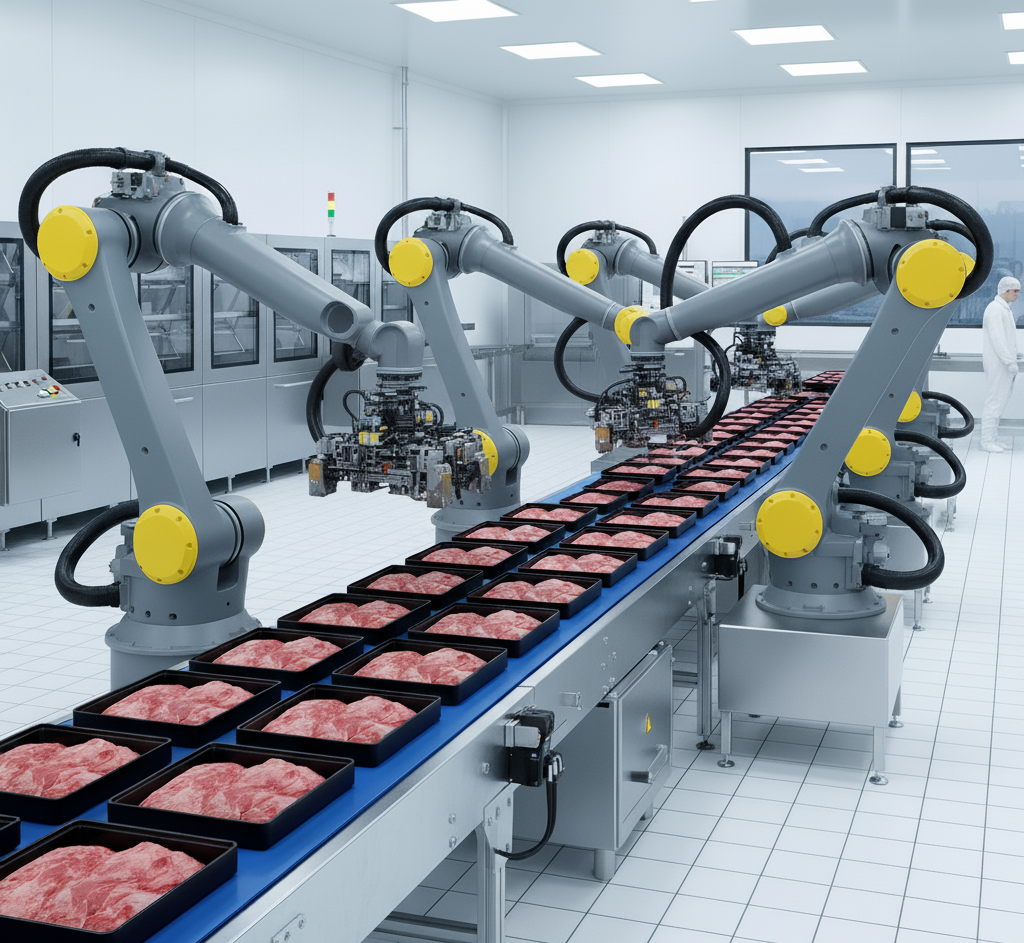

We integrate hygienic-design robots into meat and fish processes, conceived to facilitate cleaning and disinfection, and adapted to the most demanding environments.

Our robotic solutions are divided into two main areas:

Dynamic applications

The robots synchronise with the conveyor belt to handle products in motion with precision and speed. Thanks to machine vision, they detect each piece in real time and perform pick & place, sorting and continuous positioning operations. An ideal solution for high-performance lines in the food industry.

Developed applications:

– Pig singeing on slaughter lines

– Sorting of meat or fish cuts

– Stamp marking on slaughter lines

– Waterjet cutting of fish fillets

– Continuous band-saw cutting of blocks

Stationary applications

The robots operate on products at fixed stations, ensuring repeatability and safety in every cycle. This configuration is ideal for loading and unloading, stacking, packaging or cutting processes, where precision and reliability are essential.

Developed applications:

– Oriented product cutting with band saw

– Stacking and palletising of E2 crates

– Tipping boxes into containers

– Tipping product boxes onto the packaging line

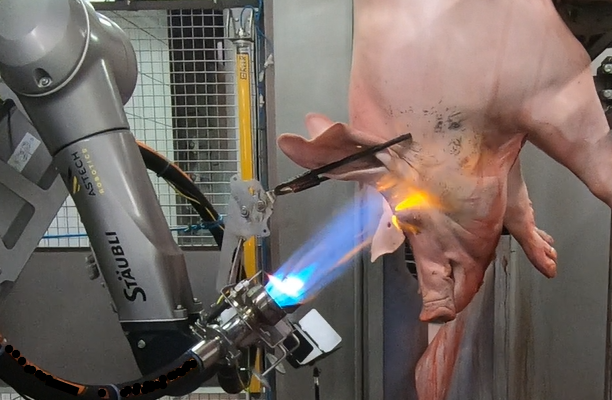

Pig singeing robot RBM-2P

Our robotic system automates the singeing of pigs, ensuring a homogeneous, high-quality finish, especially in the jowl folds, ears and eyebrows.

At the heart of the system is a six-axis Stäubli anthropomorphic robot, which adapts with total precision to different animal sizes.

The singeing process is carried out using a state-of-the-art burner, designed to deliver maximum efficiency and versatility. It can operate with propane, natural gas and, with the appropriate adaptations, even with green hydrogen, contributing to more sustainable production.

Thanks to its robust design and IP67 protection, the robot withstands industrial cleaning processes without the need for additional covers, ensuring hygiene, reliability and durability even in the most demanding environments.

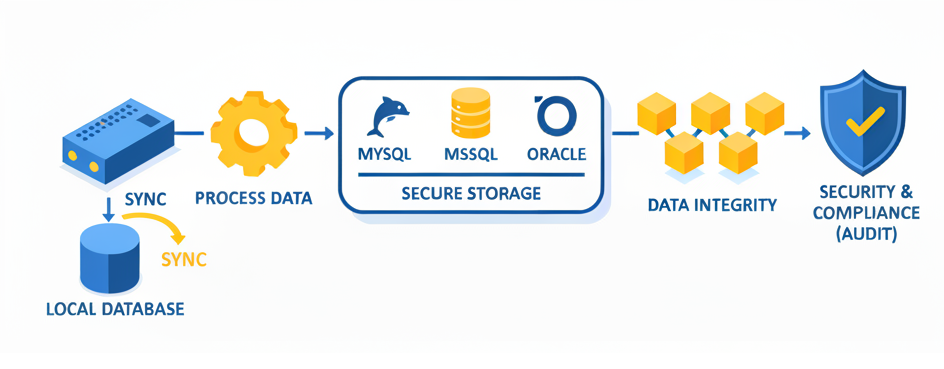

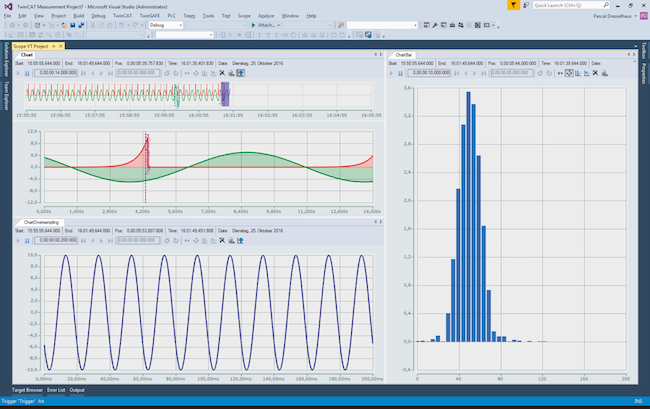

DATA ACQUISITION AND LOGGING SYSTEMS

We integrate data acquisition and management systems that connect directly with your production processes. Our solutions enable real-time data collection from multiple industrial protocols and equipment (PLC, sensors, SCADA), securely store it in databases such as MySQL, Microsoft SQL or Oracle, and transform it into valuable knowledge for decision-making.

Thanks to this digitalisation, you will be able to monitor key production indicators (KPIs) in real time, generate test result reports, traceability, line efficiency and production analysis — all from a single environment.

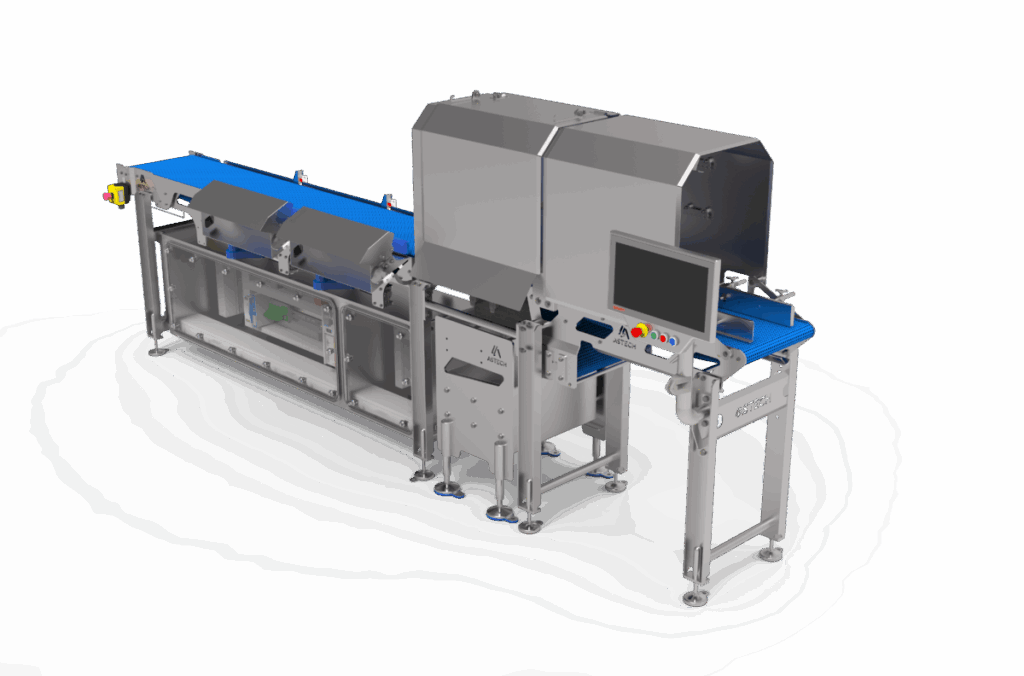

Blood component registering system

The blood component registering system fully automates the registration process of blood donation bags, ensuring traceability, quality, and consistency of all collected data.

The system automatically reads the ISBT codes of the bags, performs continuous dynamic weighing, and measures temperature using infrared sensors. Non-conforming units are automatically classified and diverted to the reject lanes, according to the detected issue.

The machine integrates communication with a local SQL database and automatic export to the corporate Oracle database, enabling direct connection to the blood bank’s corporate ERP.

Persistent data logging

We implement persistent logging systems that ensure the secure preservation of process data, essential both for internal audits and for compliance with public administration requirements.

We deploy redundant storage architectures based on synchronised databases, ensuring availability and reliability at all times. In addition, we apply Blockchain technology to verify the integrity of records, providing absolute traceability and preventing any manipulation or loss of information.

In this way, our clients have a robust and reliable system to preserve critical production information with full legal and operational guarantees.

Condition monitoring

We integrate high-precision vibration sensors and electrical parameter measurement systems (current, voltage, energy consumption) into critical plant equipment. This advanced sensor technology provides detailed information on the mechanical and electrical behaviour of industrial assets.

The data is processed using real-time analysis algorithms — such as anomaly detection, statistical trend analysis and predictive models — to anticipate failures, reduce unplanned downtime and optimise maintenance.

In this way, our clients benefit from an effective tool to extend the service life of their machines, increase reliability and ensure production continuity.

KPI analytics, reporting and dashboards

We develop systems for KPI calculation, report generation and dashboards to provide full visibility of production. Thanks to integration with Atvise SCADA, we offer a fully web-based visualisation platform that allows access to information from any device, at any time and from anywhere.

Atvise’s decentralised technology enables process monitoring without the need to install additional software, ensuring security, flexibility and scalability. This allows our clients to monitor line status in real time, generate production or test result reports, and have intuitive dashboards for strategic decision-making.